How affordable plastic injection molding solutions can help you save your business a lot of money?

How affordable plastic injection molding solutions can help you save your business a lot of money?

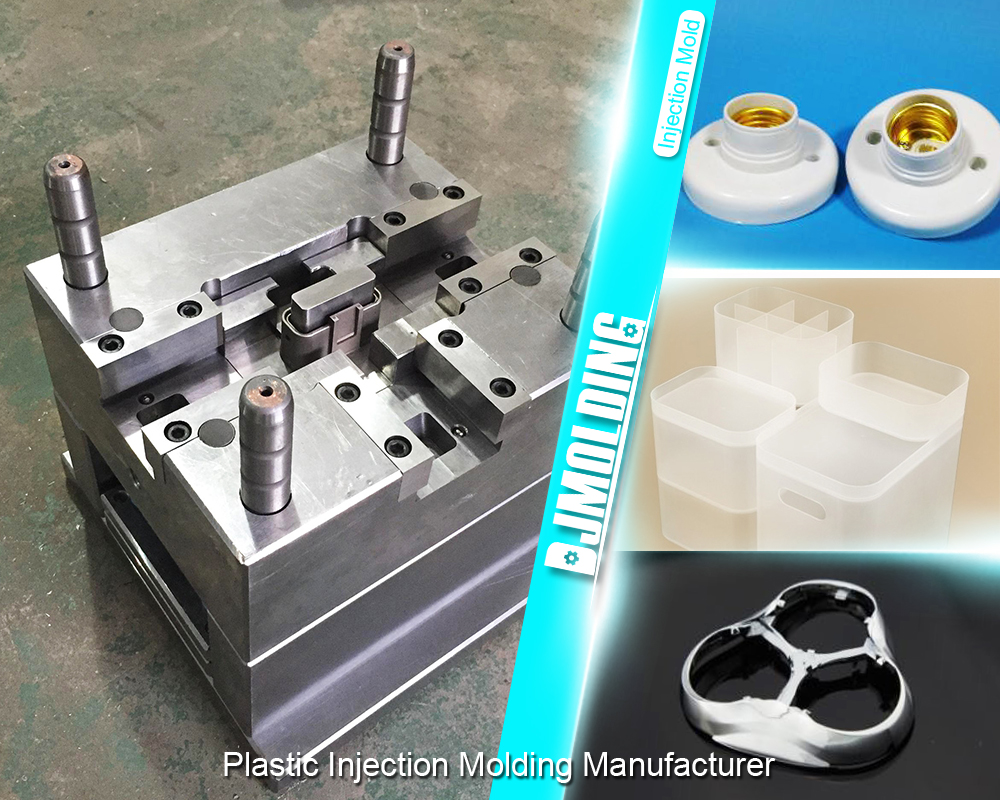

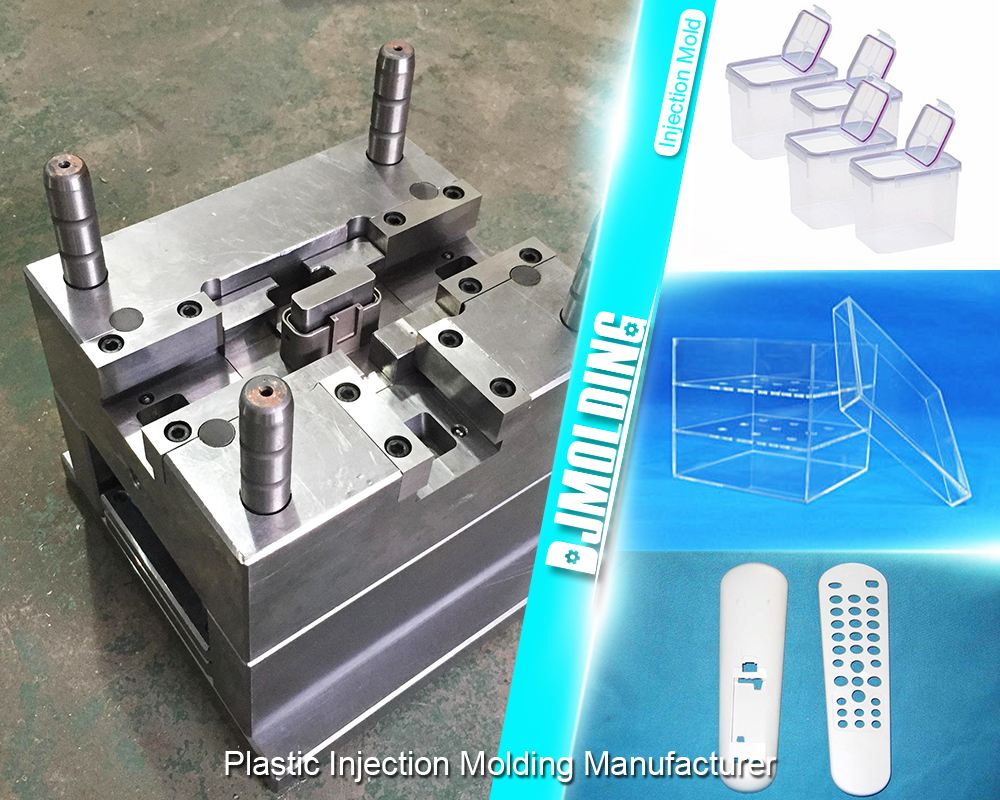

Businesses looking to produce various plastic products, accessories, and parts can rely on the many plastic injection molding solutions. These production technologies are meant to support precise and efficient production with by transforming injected molten plastics into desirable shapes and forms. This method of production is a great industrial process that can be used to produce both attractive and functional plastic products without using too many resources.

An overview on Plastic injection molding

The plastic molding injection process is a production model whereby parts are produced by the injection of molten material (like plastic) into a prepared mold. When inside the cavity, the molten material will usually cool up and become solidified. It usually assumes the shape of the mold. The plastic injection molding process is widely applied in the production of various plastic products and parts. It is known for its high consistency and precision. It is a production method that involves forcing the molten material into the molds. It works to cater for the production of delicate designs and shapes.

Benefits of the plastic injection molding solutions

Plastic injection molding solutions can be used in the production of desirable shapes. It is a very important production process for businesses looking to streamline their production workflows while also meeting the various needs of the customers. During the process of production, the plastic injection molding machine can help ensure dull accuracy, speed, and performance during high-volume production runs. Many manufacturers across various industries rely on plastic injection molding solutions to enhance the general production requirements to meet both short- and long-term goals. In this case, it pays a lot to make the process cheap and cost-effective.

How affordable is plastic injection molding?

If you use plastic injection molding for high-volume production runs, it can help your business save a lot of money. Affordable plastic injection molding solutions help manufacturers quickly produce larger volumes of products/parts. However, in this case, you will have to know that the initial capital for the business can be quite high. This is because the business will have to invest in tooling machines and molds. If you considering low-volume production, it could be cost-effective to choose other manufacturing processes. If you want to maximize your savings with this production system, then you will have to consider several features:

- The complexity of the product design

- The material needed for the production process

- The volume of the production

How businesses can save money with plastic injection molding solutions

When a business chooses affordable plastic injection molding solutions, it can save up on a lot of money. With this type of production technology, businesses can save money in different ways. These include:

- Production of products in bulk: Businesses can use this machine process for high-volume production runs to offset the production cost of each product. Businesses get to save a lot of money if they choose this production method for high-volume production runs.

- The ability to optimize product designs: With affordable plastic injection molds, businesses can choose product designs that reduce cycle times, minimize material waste, and maximize mold efficiency. This helps them to make huge savings on machine time and on product material.

- High-quality production machines and tools: With these molding solutions, businesses can save a lot of money in the invest in durable options. There are various injection molds and tools in the market. When they invest in affordable options, they can guarantee longer product life spans as well as minimal costs for product replacements.

- Selecting cost-effective production materials: Businesses can choose highly suitable and cost-effective production materials that satisfy all their requirements for the final output. This helps them to effectively balance affordability and quality, which are two core elements to ensuring consistent savings with any manufacturing business.

- Ensure optimization of the processes: Businesses should ensure that they always optimize and refine their injection molding technologies. This helps them to enhance overall efficiency, reduce scraps, and minimize product errors.

- Sharing of production tools: Businesses that emphasize the sharing of production molds and tools can help save up on costs. It involves conserving production tools and using the same across multiple customers or products. This helps to efficiently spread out the cost of tooling while also optimizing their use.

- Consider recycled plastic materials: One way businesses can save costs with affordable plastic injection molding solutions is if they rely on recycled production materials. It is important if they consider the use of recycled products in their production processes. While it will never reduce the final product quality, it can help lower the cost of the materials.

- Choose lean manufacturing processes: Affordable plastic injection molding solutions also support lean manufacturing. This is a manufacturing principle that helps businesses increase workflow efficiency by streamlining their operations. This saves a significant amount of the total production cost as it goes a long way in minimizing downtime.

- Choose automated production systems: Businesses can make use of automated systems and production robots to maximize efficiency during production runs. When this is implemented, they can also significantly reduce labour costs while also enhancing the general performance of the manufacturing facility.

- Planning for proactive maintenance and inspection: Affordable plastic injection technology will stop being affordable if they are not maintained properly. This means that businesses can easily develop a proactive schedule for maintenance. In this case, they can easily avoid expensive machine downtime and be able to extend the life of the equipment.

- Strong and profitable partnerships with suppliers: A plastic injection molding solution isn’t affordable without the support of solid supplier partnerships. It is important for businesses to create collaborative relationships with their suppliers and vendors. This makes it possible for them to negotiate better prices for bulk product purchases. A great manufacturer-supplier relationship is also necessary for profitable long-term contracts.

- Focusing on waste reduction practices: Businesses can save money with their plastic injection molding technology if they focus on minimizing waste. This is possible if they focus on efficient production methods, proper designs for product parts, and accurate measurement of materials.

Businesses that focus on these parts of the production cycle, can easily maximize efficiency and cost savings, especially with affordable plastic injection molding solutions.

For more about how affordable plastic injection molding solutions can help you save your business a lot of money,you can pay a visit to Djmolding at https://www.djmolding.com/technology-application/ for more info.