The Benefits Of Low Volume Plastic Parts Manufacturing Process For Small Businesses

The Benefits Of Low Volume Plastic Parts Manufacturing Process For Small Businesses

In today’s economy, small businesses are always looking for ways to reduce costs and improve profitability. When it comes to plastic manufacturing, high volume production may seem like the logical choice for achieving economies of scale. However, low volume plastic manufacturing is proving to be a viable option for small businesses.

In today’s article, we will explore the benefits of low volume plastic manufacturing and how it can help small businesses stay competitive in the marketplace. From cost savings to flexibility in design, we will examine the advantages of this manufacturing process and why it’s worth considering for your business.

Cost-Effective Solution for Small Businesses

Low volume manufacturing is a cost-effective solution for small businesses that require customized plastic products. Traditional manufacturing processes require large quantities of products to be produced to make the process cost-effective. However, this is not always feasible for small businesses that require smaller quantities of products. Low volume manufacturing allows small businesses to produce smaller quantities of products at a lower cost. This makes it easier for small businesses to compete with larger companies in the market.

Reduced waste and material costs are also significant benefits of low volume manufacturing. Traditional manufacturing processes often result in a significant amount of waste, which can be costly for small businesses. Low volume manufacturing reduces waste by producing only the required quantity of products. This also reduces material costs, making the process more cost-effective for small businesses.

Customization and Flexibility in Low Volume Manufacturing

Low volume manufacturing is a game-changer for small businesses looking to cater to the unique needs of their customers. With this production method, businesses can create one-of-a-kind products that are tailored to meet the specific requirements of their clients. This approach is ideal for companies that want to establish a competitive edge in the market by offering exclusive products that cannot be replicated by larger firms.

By leveraging low volume manufacturing, small businesses can enhance their brand reputation and increase customer loyalty. This production method offers businesses the flexibility to experiment with different designs, materials, and production techniques, which is crucial when creating custom products that meet the diverse needs of customers. Ultimately, low volume manufacturing empowers small businesses to create high-quality, unique products that stand out in a crowded market.

Reduced Lead Times and Faster Turnaround

Low volume manufacturing is an efficient solution for small businesses looking to streamline their production process. With shorter production times, businesses are able to deliver products to customers faster, ultimately increasing customer satisfaction and loyalty. By utilizing this method, businesses can also reduce their inventory costs and minimize waste, leading to a more sustainable and profitable operation. Overall, low volume manufacturing is a wise investment for any business looking to enhance their production capabilities and deliver quality products to their customers in a timely manner.

Quality Control and Consistency in Production

Low volume manufacturing is a highly effective means of ensuring consistent product quality. This approach to production involves producing smaller quantities of a product, typically in the range of 100 to 10,000 units, rather than mass producing large volumes. By focusing on smaller quantities, manufacturers are able to meticulously monitor every stage of the production process to ensure that each product meets the highest standards of quality.

One of the key benefits of low volume manufacturing is that it enables manufacturers to identify and address any issues with their products early on in the production process. This means that any defects or inconsistencies can be quickly identified and corrected, reducing the likelihood of faulty products reaching the market. Additionally, because each product is produced with greater care and attention, the quality of the finished product is typically higher than that of mass-produced goods.

Lower Risk and Minimal Investment

Low volume manufacturing is an excellent solution for small businesses looking to reduce their financial risk. With low volume manufacturing, businesses can produce a smaller quantity of products without having to invest in expensive equipment or large production runs. This approach allows small businesses to test the market and evaluate demand for their products without incurring high costs.

Compared to traditional manufacturing methods, it and can help small businesses save money. By producing a smaller quantity of products, small businesses can minimize their inventory costs and reduce the risk of overproduction. This approach also allows businesses to adjust their production levels based on market demand, which can help them stay competitive in the market.

Sustainability and Environmental Benefits

Low volume manufacturing is also beneficial for the environment. It reduces waste and energy consumption, which has a positive impact on the environment. The use of eco-friendly materials also reduces the environmental impact of the manufacturing process. This is particularly important for small businesses that want to promote sustainability and environmental responsibility.

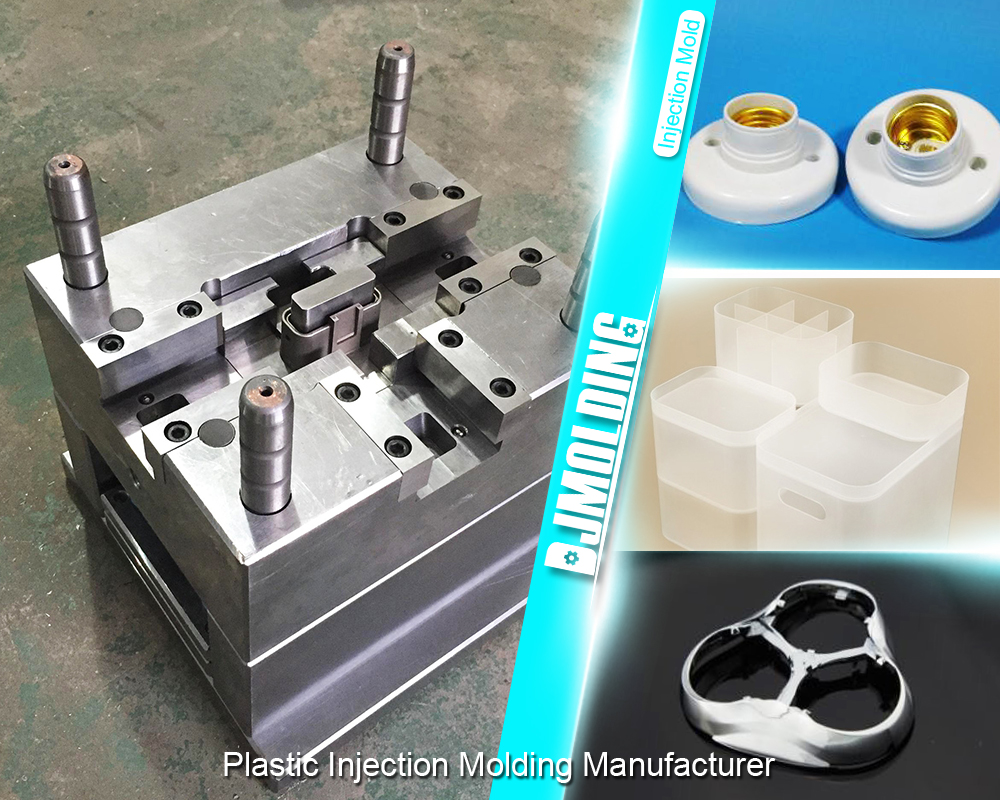

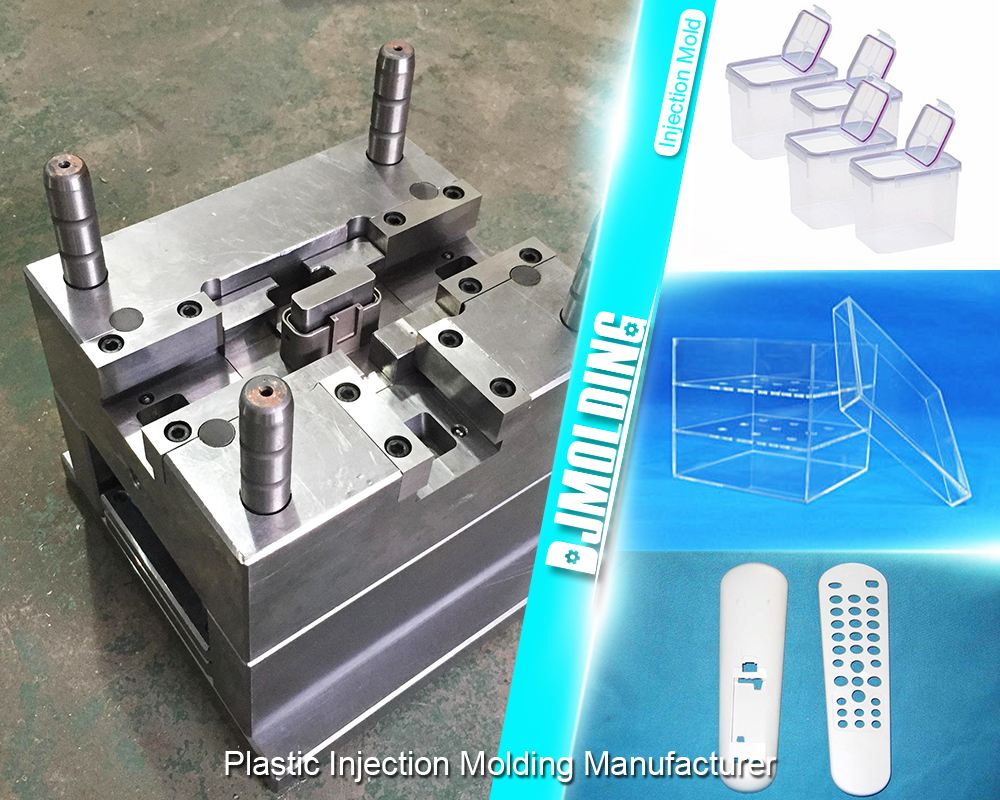

Access to Advanced Manufacturing Technologies

Low volume manufacturing allows small businesses to access advanced manufacturing technologies that were previously only available to larger companies. This improves efficiency and accuracy, which increases competitiveness in the market. Small businesses can now produce high-quality products that meet customer needs and preferences.

Competitive Advantage in the Market

Low volume manufacturing gives small businesses a competitive advantage in the market. The ability to offer unique products, faster turnaround times, and improved customer satisfaction can help small businesses stand out in a crowded market. This can lead to increased sales and revenue, which is essential for the growth and success of small businesses.

Conclusion: Low Volume Plastic Manufacturing as a Game-Changer for Small Businesses

In conclusion, low volume plastic manufacturing is a game-changer for small businesses. It provides a cost-effective solution for businesses that require customized plastic products. The flexibility in design changes, reduced lead times, and faster turnaround times also make it easier for small businesses to compete with larger companies in the market.

The benefits of low volume manufacturing, including sustainability and environmental benefits, access to advanced manufacturing technologies, and a competitive advantage in the market, make it a viable option for small businesses. Small businesses should consider low volume manufacturing as a way to grow and succeed in the market.

For more about the benefits of low volume plastic parts manufacturing process for small businesses,you can pay a visit to Djmolding at https://www.djmolding.com/low-volume-manufacturing-service/ for more info.