The Future Of Sustainable Small Batch Plastic Manufacturing With Small Scale Injection Molding

The Future Of Sustainable Small Batch Plastic Manufacturing With Small Scale Injection Molding

Small batch plastic manufacturing has gained significant popularity in recent years, as it enables businesses to create customized products tailored to their consumers’ needs. However, the detrimental effects of plastic on the environment cannot be ignored, prompting the need for sustainable manufacturing methods. As the world becomes more conscious of the impact of plastic waste on the environment, the future of small batch plastic manufacturing lies in sustainability.

Today, we will explore the future of sustainable small batch plastic manufacturing, including the latest developments in technology and the benefits of adopting eco-friendly practices.

Understanding Sustainable Small Batch Plastic Manufacturing

Sustainable small batch plastic manufacturing refers to the production of plastic products in small quantities using environmentally friendly practices. This process is all about producing plastic products in small quantities while minimizing the impact on the environment. The use of renewable energy sources helps to reduce carbon emissions, while recycling waste materials ensures reduced waste. Small batch manufacturing is advantageous as it allows for customization, flexibility in production, and most importantly, a safe environment for both workers and consumers.

The manufacturing process is carefully monitored to ensure that products are made according to established standards, without compromising on quality. Sustainable small batch plastic manufacturing is the way to go for businesses that want to make a positive impact on the environment while still meeting consumer demand.

The Importance of Sustainable Manufacturing Practices

Sustainable manufacturing practices have become increasingly important in recent years, as companies recognize the need to minimize their impact on the environment and society as a whole. The benefits of sustainable manufacturing practices are numerous, ranging from reduced waste and energy consumption to improved employee morale and customer loyalty.

By adopting sustainable manufacturing practices, companies can reduce their carbon footprint and conserve natural resources. This can be achieved through measures such as energy-efficient machinery, recycling programs, and the use of renewable energy sources. Not only does this benefit the environment, but it can also lead to cost savings for the company in the long run.

In addition to environmental benefits, sustainable manufacturing practices can also improve employee morale and customer loyalty. Employees are more likely to feel proud of their work and be motivated by a company that prioritizes sustainability. Customers are increasingly demanding sustainable products and are more likely to remain loyal to a company that demonstrates a commitment to sustainability.

The Future of Sustainable Small Batch Plastic Manufacturing

The future of sustainable small batch plastic manufacturing is promising. There is a growing trend towards sustainable manufacturing practices, and consumers are becoming more environmentally conscious. The use of renewable energy sources, recycling of waste materials, and reduction of carbon emissions will continue to be a focus in the future. The demand for sustainable products will also increase, leading to the growth of sustainable small batch plastic manufacturing.

Innovations in Sustainable Plastic Manufacturing Technology

Innovations in sustainable plastic manufacturing technology are emerging. New technologies are being developed to reduce the environmental impact of plastic production. These technologies include the use of biodegradable materials, 3D printing, and the use of renewable energy sources. Biodegradable materials are becoming more popular as they break down naturally and do not contribute to environmental pollution. 3D printing allows for the production of customized products, reducing waste and increasing efficiency. The use of renewable energy sources such as solar and wind power reduces carbon emissions and promotes sustainability.

The Role of Circular Economy in Small Batch Plastic Manufacturing

Circular economy refers to the process of reducing waste and promoting the reuse of materials. In small batch plastic manufacturing, circular economy practices can be used to reduce waste and promote sustainability. This involves the use of recycled materials, reducing the use of non-renewable resources, and promoting the reuse of products. Circular economy practices also promote the use of environmentally friendly materials and reduce waste.

The Impact of Sustainable Manufacturing on the Environment

Sustainable manufacturing has a positive impact on the environment. It reduces the use of non-renewable resources, promotes the use of renewable energy sources, and reduces carbon emissions. Sustainable manufacturing also promotes the use of environmentally friendly materials and reduces waste. Compared to traditional manufacturing practices, sustainable manufacturing has a significantly lower environmental impact.

The Economic Benefits of Sustainable Small Batch Plastic Manufacturing

Sustainable small batch plastic manufacturing has economic benefits. It reduces production costs by promoting the use of renewable energy sources, reducing waste, and promoting efficiency. Sustainable products also have a higher demand, leading to increased sales and revenue. Sustainable manufacturing practices also promote innovation and creativity, leading to the development of new products and services.

Current Challenges to Sustainable Small Batch Plastic Manufacturing

As the world continues to grapple with the environmental impact of plastic, small batch plastic manufacturing faces several challenges in achieving sustainability.

One of the biggest problems is the lack of infrastructure for recycling and reusing small batches of plastic. Large-scale manufacturers have the resources to invest in recycling and reuse programs, but small batch manufacturers often find it difficult to implement such programs due to the high costs involved.

Another challenge is the limited availability of sustainable materials for small batch plastic production. Many manufacturers rely on traditional plastics, which are made from non-renewable resources and have a negative impact on the environment. While there are sustainable alternatives available, they are often more expensive and difficult to source.

In addition, small batch manufacturers face challenges in reducing waste during the production process. Unlike large-scale manufacturers who can invest in sophisticated machinery and processes, small batch manufacturers often have limited resources to optimize their production processes.

Conclusion

Sustainable small batch plastic manufacturing is essential for promoting sustainability and reducing the environmental impact of plastic production. Collaboration and innovation are necessary for the growth of sustainable manufacturing practices. Manufacturers and consumers must prioritize sustainability to promote a more sustainable future. The use of renewable energy sources, recycling of waste materials, and reduction of carbon emissions must be a focus in the future. Sustainable small batch plastic manufacturing has economic benefits, promotes innovation, and reduces the environmental impact of production.

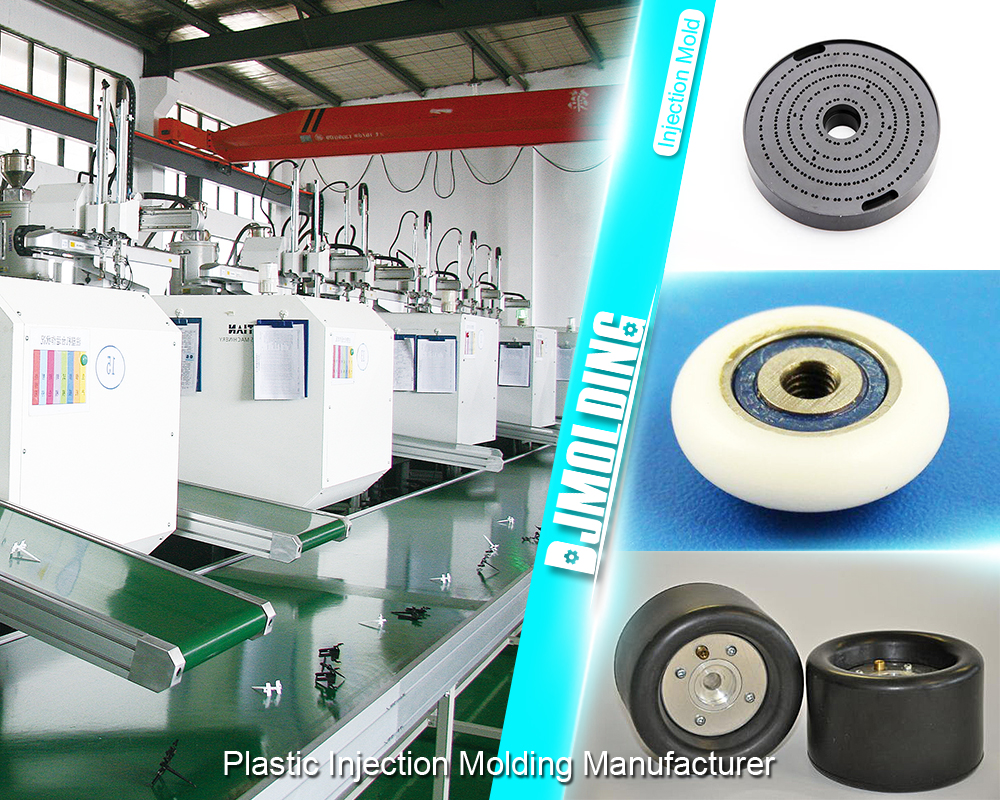

For more about the future of sustainable small batch plastic manufacturing with small scale injection molding,you can pay a visit to Djmolding at https://www.djmolding.com/low-volume-injection-molding/ for more info.