Maximizing Sustainability: The Power Of Recycled Plastic Injection Molding For Plastic Parts

Maximizing Sustainability: The Power of Recycled Plastic Injection Molding For Plastic Parts

Recycled plastic injection molding is revolutionizing the manufacturing industry by offering an eco-friendly solution to address the increasing global concern for sustainability. As the demand for sustainable practices grows, exploring innovative manufacturing techniques that reduce environmental impact becomes crucial. This blog post will delve into the benefits, applications, and challenges of recycled plastic injection molding, shedding light on its potential to shape a more sustainable future.

The Basics of Recycled Plastic Injection Molding

Recycled plastic injection molding is a manufacturing process that offers a sustainable solution to address environmental concerns. By understanding the basics of this technique, manufacturers can harness its potential to reduce waste and promote a circular economy. Here are some key points regarding the basics of recycled plastic injection molding:

Definition and Process Overview

Recycled plastic injection molding involves melting down recycled plastic materials and injecting them into molds. The process begins with collecting and sorting recyclable plastics, followed by cleaning and shredding to prepare the materials for the molding process. The injection process injects the melted plastic into a mold cavity, solidifying it to take its shape.

Types of Plastics Suitable for Recycled Injection Molding

Recycled plastic injection molding utilizes various types of plastics, such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), polypropylene (PP), and polystyrene (PS). These plastics commonly appear in packaging materials, bottles, and other consumer products.

Advantages of Using Recycled Plastics in Injection Molding

Recycled plastic injection molding offers several benefits

- It contributes to environmental sustainability by reducing virgin plastic consumption and diverting plastic waste from landfills.

- Using recycled plastics in injection molding can save manufacturers’ costs, as recycled materials are often less expensive than their virgin counterparts.

- The process promotes energy efficiency since recycled plastics require less energy to melt and methodology compared to virgin plastics.

Incorporating recycled plastic injection molding into manufacturing processes supports sustainable practices and offers economic advantages. Companies can use recycled plastics to reduce their environmental footprint, lower costs, and contribute to a more circular economy.

Applications of Recycled Plastic Injection Molding

Recycled plastic injection molding has various applications across various industries, providing sustainable solutions and promoting environmental responsibility. Here are some key points highlighting the applications of recycled plastic injection molding:

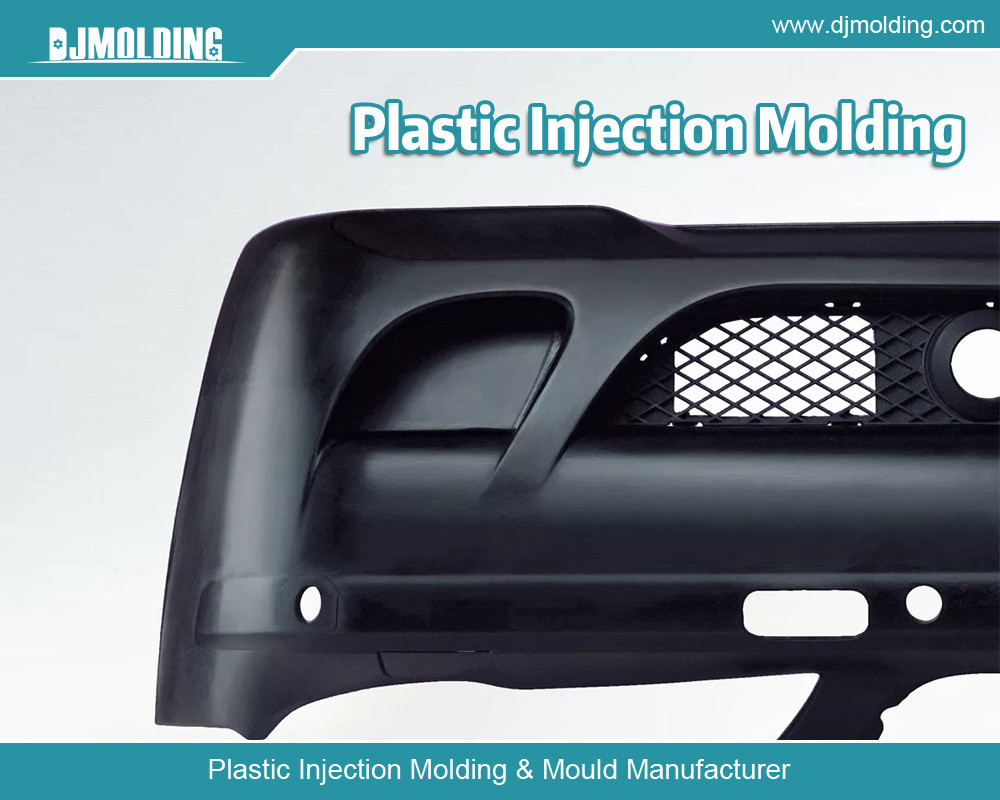

- Automotive Industry: Recycled plastic injection molding plays a vital role in the automotive sector. It uses recycled plastics to produce interior components, such as dashboards, door panels, and seat backs. Additionally, manufacturing exterior parts like bumpers and fenders can benefit from recycled plastic injection molding, offering both sustainability and cost-saving advantages.

- Packaging Sector: Sustainable packaging solutions are in high demand, and recycled plastic injection molding provides an ideal solution. By utilizing recycled plastics, manufacturers can create packaging materials that are environmentally friendly and visually appealing. From food packaging to cosmetic containers, recycled plastic injection molding offers versatility and reduces the need for virgin plastics, contributing to a greener packaging industry.

- Electronics and Appliances: Recycled plastic injection molding finds application in producing enclosures and housings for electronic devices and appliances. These components can be made from recycled plastics, ensuring durability and performance while reducing the reliance on virgin plastics. Sustainable consumer electronics and household appliances benefit from this manufacturing technique, aligning with the growing demand for eco-friendly products.

The applications of recycled plastic injection molding extend beyond these sectors, with possibilities in industries such as furniture, toys, and building materials. By embracing this sustainable manufacturing technique, companies can meet consumer demands for eco-friendly products while minimizing their environmental impact. Recycled plastic injection molding opens new avenues for creativity, innovation, and a more sustainable future.

Challenges and Considerations

While recycled plastic injection molding offers numerous benefits, there are also specific challenges and considerations that manufacturers should be aware of. Understanding these challenges is crucial to successfully implementing recycled plastic injection molding and maximizing its effectiveness. Here are some key points highlighting the challenges and considerations associated with this manufacturing technique:

- Quality Control and Material Consistency: Maintaining consistent material properties is essential for producing high-quality products. Recycled plastics can vary in composition and quality, which poses challenges in achieving consistent results. Implementing rigorous quality control measures, including thorough material testing and monitoring, helps ensure material consistency and product reliability.

- Design Limitations and Compatibility: Designing products for recycled plastic injection molding may involve certain limitations. Recycled plastics can have different flow characteristics and shrinkage rates than virgin plastics, which may require design adjustments. Manufacturers should also consider compatibility with existing molds, equipment, and manufacturing processes to ensure a smooth transition to recycled plastics.

- Industry Standards and Regulations: Adhering to industry standards and regulations is vital for ensuring product safety and compliance. Recycled plastic materials must meet specific criteria and certifications to guarantee their suitability for injection molding applications. Manufacturers should stay updated on relevant regulations and work with suppliers who provide certified recycled plastics.

- Addressing Perceived Consumer Concerns: Some consumers may have concerns about using recycled plastics, such as doubts about product quality or potential health risks. It is crucial to address these concerns proactively through effective communication and transparency. Providing clear information about recycled plastic materials’ sourcing, processing, and performance can help build trust and overcome potential barriers.

Overcoming these challenges requires a comprehensive approach that includes thorough material selection, design optimization, quality control measures, and adherence to industry standards. By addressing these considerations, manufacturers can mitigate risks and maximize the benefits of recycled plastic injection molding. Embracing sustainable manufacturing practices while ensuring product quality and compliance contributes to a more environmentally friendly and socially responsible approach to production.

Best Practices for Successful Recycled Plastic Injection Molding

To ensure successful recycled plastic injection molding, manufacturers should follow certain best practices that optimize the process and maximize the benefits of using recycled plastics. Here are some key points highlighting the best practices for successfully recycled plastic injection molding:

- Material Selection and Sorting: Proper material selection is essential for achieving high-quality results. Choosing recycled plastics suitable for injection molding and meeting the required specifications is vital. Additionally, sorting the recycled materials based on their type, grade, and quality helps ensure consistent and reliable performance.

- Pre-processing Techniques: Pre-processing techniques, such as cleaning and shredding, are critical for preparing recycled plastics before injection molding. Thoroughly cleaning the materials removes contaminants, ensuring the final product’s integrity. Shredding the plastics into small, uniform pieces enhances their melt flow and facilitates easier processing during injection molding.

- Equipment and Tooling Considerations: Recycled plastic injection molding may require specific considerations when it comes to equipment and tooling. It is vital to optimizing the machinery settings, such as temperature control and injection speed, to accommodate the characteristics of recycled plastics. Additionally, molds and tooling designed explicitly for recycled plastics help achieve the desired product quality and dimensional accuracy.

- Design Optimization for Recycled Plastics: Design plays a crucial role in successful recycled plastic injection molding. To optimize the part geometry, designers should consider the unique properties of recycled plastics, such as shrinkage rates and flow characteristics. By designing with recycled plastics in mind, it is possible to achieve better mold filling, reduced warpage, and improved overall part performance.

By following these best practices, manufacturers can overcome challenges associated with recycled plastic injection molding and achieve successful outcomes. These practices promote consistency, efficiency, and the ability to create high-quality products while embracing sustainability. Implementing these best practices benefits the environment and contributes to cost savings, resource conservation, and a greener future.

Case Studies: Success Stories and Real-World Examples

Several companies have embraced recycled plastic injection molding and achieved remarkable success. Company A, for instance, has successfully integrated recycled plastics into its manufacturing process, achieving its sustainability goals while maintaining product quality. Company B stands out with innovative applications of recycled plastic injection molding, gaining a competitive edge in the market. Meanwhile, Company C has overcome challenges associated with recycled plastics, maximizing efficiency and reaping sustainability benefits.

Conclusion

Recycled plastic injection molding presents an incredible opportunity to maximize sustainability in the manufacturing industry. Manufacturers can reduce their environmental footprint by understanding its basics, exploring diverse applications, addressing challenges, and implementing best practices while enjoying economic advantages. Emphasizing the importance of this technique, we encourage further research, development, and adoption of recycled plastic injection molding. Together, individuals, businesses, and policymakers can promote a circular economy and pave the way for a greener future.

For more about the power of recycled plastic injection molding for plastic parts,you can pay a visit to Djmolding at https://www.djmolding.com/recycled-plastic-injeciton-molding/ for more info.