The Art Of Small Batch Plastic Injection Molding: Streamlining Production With Precision

The Art Of Small Batch Plastic Injection Molding: Streamlining Production With Precision

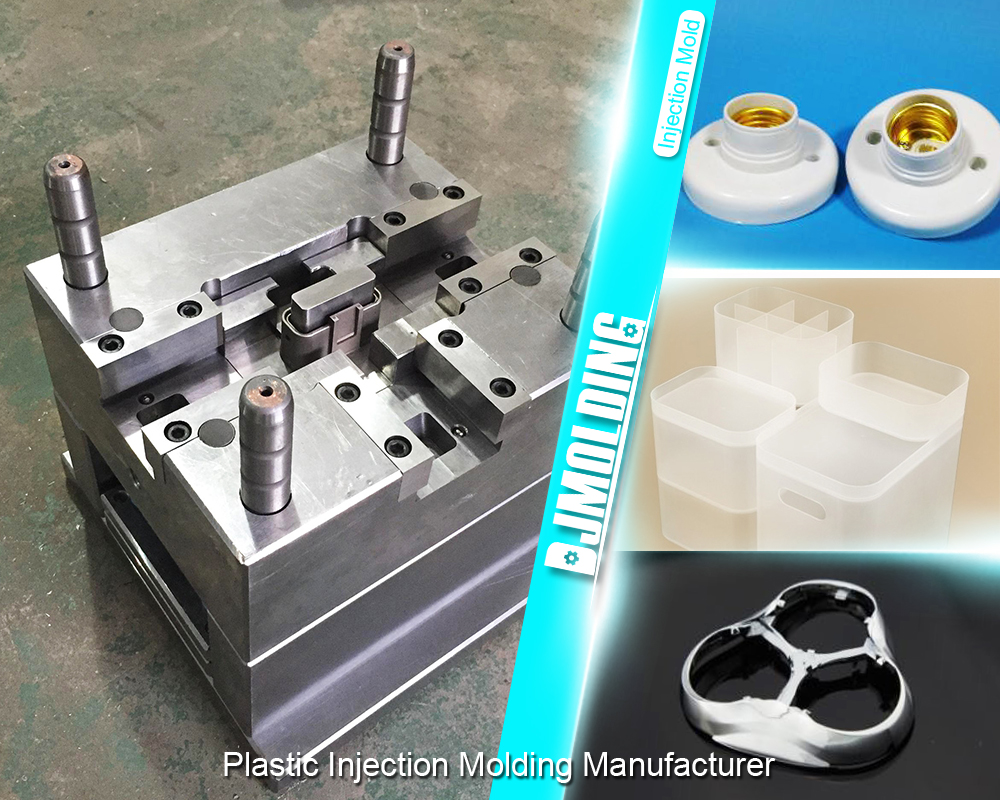

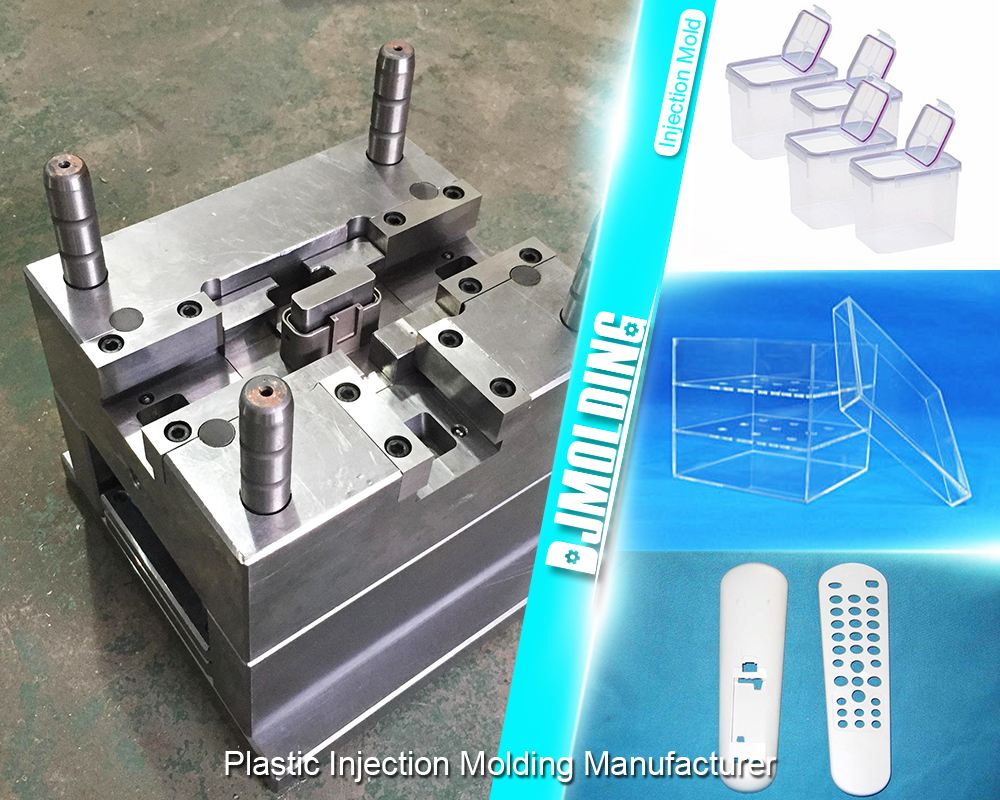

Plastic injection molding has emerged as a game-changing technique in today’s fast-paced manufacturing landscape. Harnessing precision and efficiency enables the mass production of intricate plastic components. This article delves into the intricacies of plastic injection molding, highlighting its significance, advantages, and applications across diverse industries.

Understanding Small Batch Plastic Injection Molding

Definition and Process Overview

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity to create complex and precise shapes. This section explains the core process steps, from material selection to using key components such as molds, injection units, and clamping systems.

Types of Plastics Used

The success of plastic injection molding relies on utilizing different types of plastics tailored to specific applications. Here, we explore the most commonly used plastics, including thermoplastics and thermosetting polymers. By understanding their unique characteristics and properties, manufacturers can optimize the molding process for superior results.

Key Advantages of Plastic Injection Molding

Plastic injection molding offers numerous advantages over other manufacturing methods. This section delves into its cost-effectiveness, design flexibility, high production efficiency, and consistent quality control. Real-world examples and success stories further illustrate the transformative impact of plastic injection molding on various industries.

The Plastic Injection Molding Process

Mold Design and Preparation

Mold design is a critical aspect of plastic injection molding. We discuss the importance of designing molds for optimal functionality, durability, and efficient production. Additionally, we touch on different mold materials and their properties to ensure the selection of the most suitable option for each project.

Injection Phase

The injection phase involves melting the plastic material, pressurizing it, and injecting it into the mold cavity. Here, we provide a detailed explanation of this phase, emphasizing the significance of precision and control. Manufacturers explore temperature, pressure, and cooling time to achieve product quality.

Cooling and Solidification

The cooling phase plays a crucial role in the plastic injection molding process. We explore the cooling techniques to ensure proper plastic solidification, enhancing structural integrity and minimizing defects. Experts discuss strategies such as mold temperature control, conformal cooling, and rapid cooling methods.

Ejection and Finishing

The mold ejects the product after solidification. This section explains the ejection process and highlights secondary operations such as trimming, polishing, and surface finishing. By addressing these finishing touches, manufacturers can enhance the product’s aesthetics, functionality, and marketability.

Applications of Plastic Injection Molding

- Consumer Products: Manufacturers widely use plastic injection molding to produce consumer goods. Manufacturers use this technique to manufacture kitchenware, household appliances, toys, and electronics. The versatility of plastic injection molding allows for the creation of intricate designs, vibrant colors, and durable products that enhance our everyday lives.

- Automotive Industry: The automotive industry heavily relies on plastic injection molding to produce various components. From interior trims and dashboard panels to exterior parts like bumpers and grilles, plastic injection molding offers design flexibility, weight reduction, and cost-effectiveness. It enables the automotive industry to achieve aesthetic appeal, functional integration, and improved fuel efficiency.

- Medical and Healthcare: Plastic injection molding is critical in the medical and healthcare sectors. Manufacturers use it to manufacture medical devices, equipment, and consumables with strict quality standards and regulatory compliance. Manufacturers produce items like syringes, IV connectors, surgical instruments, and implants using biocompatible materials to ensure patient safety and precise functionality.

- Packaging Industry: Plastic injection molding is instrumental in the packaging industry. It enables the production of plastic containers, bottles, caps, and closures used in various sectors such as food and beverages, personal care, and pharmaceuticals. The ability to create customized shapes, sizes, and features makes plastic injection molding a preferred choice for packaging solutions.

- Electronics and Electrical Components: Plastic injection molding significantly benefits the electronics industry. It facilitates the production of casings, connectors, switches, and other intricate parts required for electronic devices and electrical systems. Plastic injection molding ensures precision, dimensional stability, and protection against environmental factors for electronics products.

- Aerospace and Defense: Plastic injection molding finds applications in the aerospace and defense sectors. Manufacturers use plastic injection molding to produce lightweight, high-strength components that meet stringent performance and safety requirements. Examples include interior fittings, instrument panels, brackets, and aerospace ducting systems.

- Construction and Building Materials: Plastic injection molding contributes to the construction industry by producing materials such as pipes, fittings, insulation, and roofing components. The durability, corrosion resistance, and cost-effectiveness of plastic injection molded products make them ideal for construction applications.

- Sports and Recreation: Plastic injection molding produces sports equipment, recreational products, and outdoor gear. Manufacturers have items like helmets, protective gear, ball components, and equipment handles using this process. Plastic injection molding allows for the creation of lightweight, impact-resistant products that enhance performance and safety.

Advancements and Future Trends

Technological Innovations

- Automation: Automation has revolutionized plastic injection molding, streamlining production processes and improving efficiency. Automated systems can handle material handling, mold changes, and quality control, reducing human error and increasing productivity.

- 3D Printing: Integrating 3D printing technology with plastic injection molding has opened up new possibilities for rapid prototyping and customization. 3D-printed molds and inserts can be used alongside traditional molds, allowing faster iterations and cost-effective small-batch production.

- Artificial Intelligence (AI): AI plays an increasingly important role in plastic injection molding. AI-powered software can analyze process data in real time, optimizing parameters such as temperature, pressure, and cooling time for improved part quality. Predictive AI-powered maintenance systems can also help prevent unexpected downtime and reduce maintenance costs.

- Multi-Material Molding: The ability to use multiple materials in a single injection molding process is gaining traction. Manufacturers can use plastic injection molding to create complex parts with varying material properties, such as combining rigid and flexible plastics. This manufacturing technique allows for precise control over the molding process, making achieving a wide range of part designs and geometries possible. Multi-material molding expands design possibilities and enhances product functionality.

- Micro-Injection Molding: Miniaturization is a growing trend across industries, and micro-injection molding caters to this demand. This technique produces high-precision tiny, intricate parts, opening up opportunities in sectors like electronics, medical devices, and microfluidics.

- Sustainable Materials: As sustainability becomes a top priority, the industry is exploring alternative materials for plastic injection molding. Biodegradable and bio-based plastics derived from renewable sources are gaining popularity. Additionally, using recycled plastics reduces waste and supports the circular economy.

- Smart Manufacturing: Integrating Internet of Things (IoT) technology in plastic injection molding allows for intelligent monitoring and control of production processes. Sensors and connectivity enable real-time data collection, analysis, and remote monitoring. Using automated techniques in plastic injection molding enhances quality control, reduces downtime, and improves overall operational efficiency. These processes can include automatic material handling, robotic part removal, and in-line inspection systems.

- Virtual and Augmented Reality: In plastic injection molding, designers and engineers use virtual and augmented reality technologies to validate designs and optimize processes. Manufacturers can identify potential issues, optimize designs, and reduce time-to-market by creating virtual prototypes and simulating the molding process.

These advancements and future trends in plastic injection molding are shaping the industry’s landscape, making production faster, more efficient, and environmentally friendly. By embracing automation, leveraging 3D printing and AI, exploring new materials, and adopting intelligent manufacturing practices, manufacturers can stay competitive and meet the evolving demands of the market. The continuous pursuit of innovation ensures that plastic injection molding remains at the forefront of modern manufacturing.

Conclusion

Plastic injection molding is a cornerstone of modern manufacturing, enabling the efficient production of complex plastic components. Plastic injection molding has transformed products by revolutionizing core process steps, providing various advantages, and finding applications across multiple industries. Manufacturers can meet consumers’ ever-growing demands by leveraging precision, design flexibility, and cost-effectiveness. The plastic injection molding industry is poised for a future full of innovation and environmental responsibility as technological advancements and sustainability efforts continue to shape it. We invite readers to explore further and discover the boundless possibilities that plastic injection molding offers.

For more about small batch plastic injection molding,you can pay a visit to Djmolding at https://www.djmolding.com/injection-mould-manufacturing/ for more info.